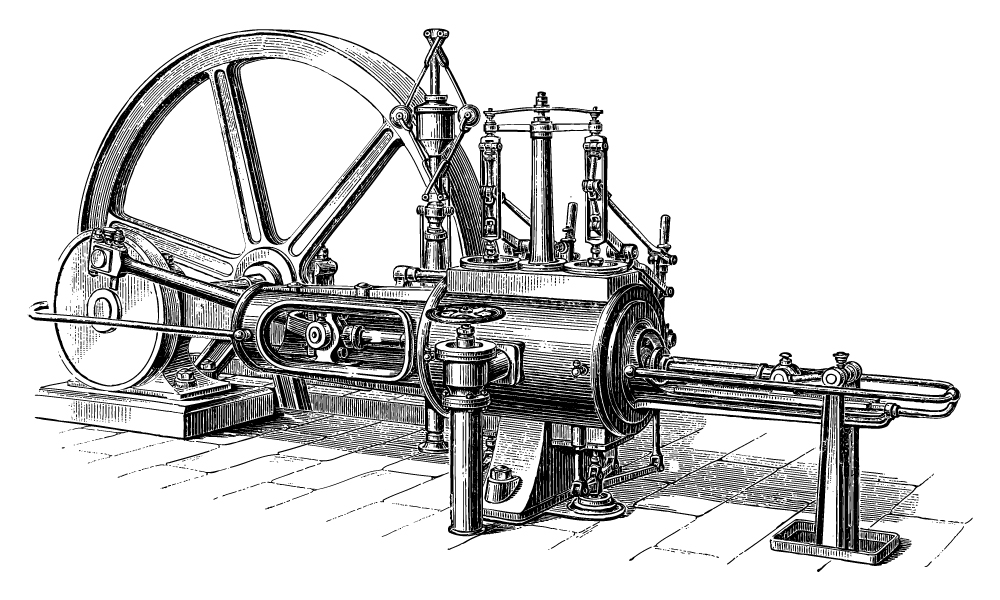

The first industrial revolution occurred from about the 1760s to the 1820s—1840s, where steam power and mechanisation drove the evolution of the global economy from one based on manual labour and agriculture to machine-augmented production and manufacturing.

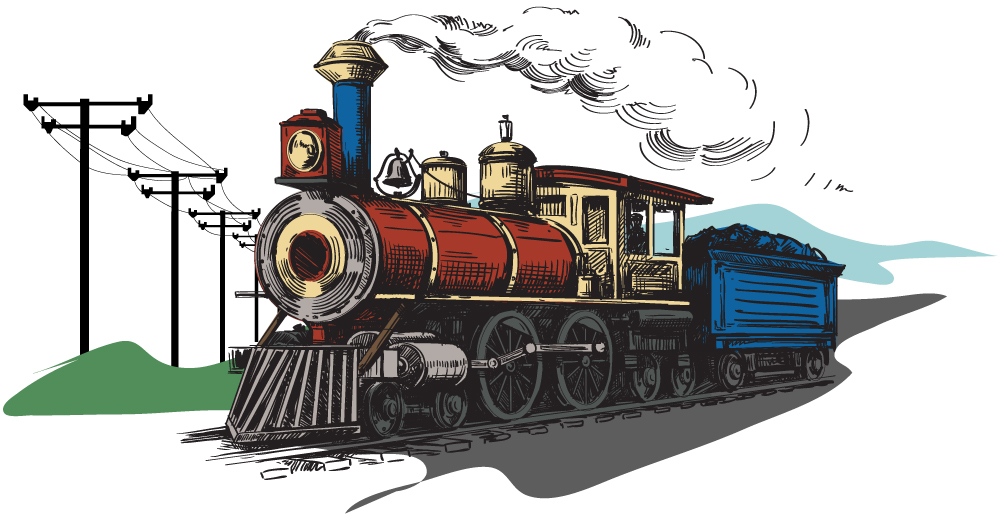

The second industrial revolution, stretching from roughly the 1870s to the 1910s, was more focused on power (e.g. electricity, gas and oil) and connectivity (e.g. transportation like rail, shipping and automobiles; as well as telecommunications such as the telegraph and the telephone).

The third industrial revolution, also known as the Digital Revolution, started around the late 1940s to 1960s. This revolution was generally based on the rise of computers and the Internet, as well as related technologies.

Industry 4.0 draws from the past revolutions in that has to do with the application of the advances of the Digital Revolution (and other emerging technologies) to manufacturing and industry.

In general, Industry 4.0 is about increasing automation, efficiency and productivity through increased use of technologies like sensors, data and analytics, machine learning and artificial intelligence (AI), robotics and automation (including drones and autonomous devices), additive manufacturing (3-D printing), and networking. However, technology is not the only focus of Industry 4.0. The successful implementation of these advances also necessitates changes in process.

An example of how technology and process come together in Industry 4.0 could involve how a factory in this age would operate. To begin, most of the manufacturing would be automated with machines, drones and robotics. Sensors would be installed throughout the facility, monitoring everything from wear-and-tear of production equipment to quality of products.

Data collected from this would then be analysed, possibly using algorithms and artificial intelligence, to identify where efficiency could be improved and to predict where issues may occur. An intelligent control system would then tweak the operation of the factory to optimise production, or address breakdowns before they happen. This system would likely be integrated with others via a network, allowing for the entire end-to-end operation of the factory to be coordinated.

In a preventive maintenance scenario for example, the sensor system may collect data about the operation of a piece of manufacturing equipment, which another analytics system then uses to predict when a particular machine part may need replacing. This prediction could then be fed into a maintenance system, which would trigger an additive manufacturing system to make the part required, and dispatch a drone to replace the part on the machine during a suitable lull in the production line (as may be identified by a sales and marketing system).

In a sense, this can be seen as a sort of self-running factory. However, transitioning existing factories into Industry 4.0 factories requires thinking and planning to reorganise how operations are currently carried out. Here is where Industry 4.0-ready talent come in. These are multidisciplinary professionals who can integrate their expertise across disciplines to support the delivery of products and services in age of Industry 4.0. Such talent are likely to have technical knowledge and skills in the technology domain, as well as in data analytics and business processes. For more about the future of work and the kinds of jobs that may be most in-demand in the fourth industrial revolution, check out this article.